Repatriating Production Back into Canada

About

Flexcim Manufacturing Services Inc. is a diverse Canadian manufacturing company located in Edmonton, Canada. Our mission is to reverse the trend towards offshoring and repatriate production into Canada.

All of our products are proudly made in Canada. We work within the community and source the majority of our supplies and materials locally. As a result, we have a good relationship with many local businesses. Our relationships with customers are vertically integrated into our manufacturing process. Orders are immediately shipped from stock and replenished based on the “Supermarket” model in lean manufacturing.

Services

Product Development

Product Development

If you have a product to develop or an idea to make real, Flexcim is the manufacturer you want on your side. Our technical team prides itself in our pledge of, “Problem Solving in a Day.”

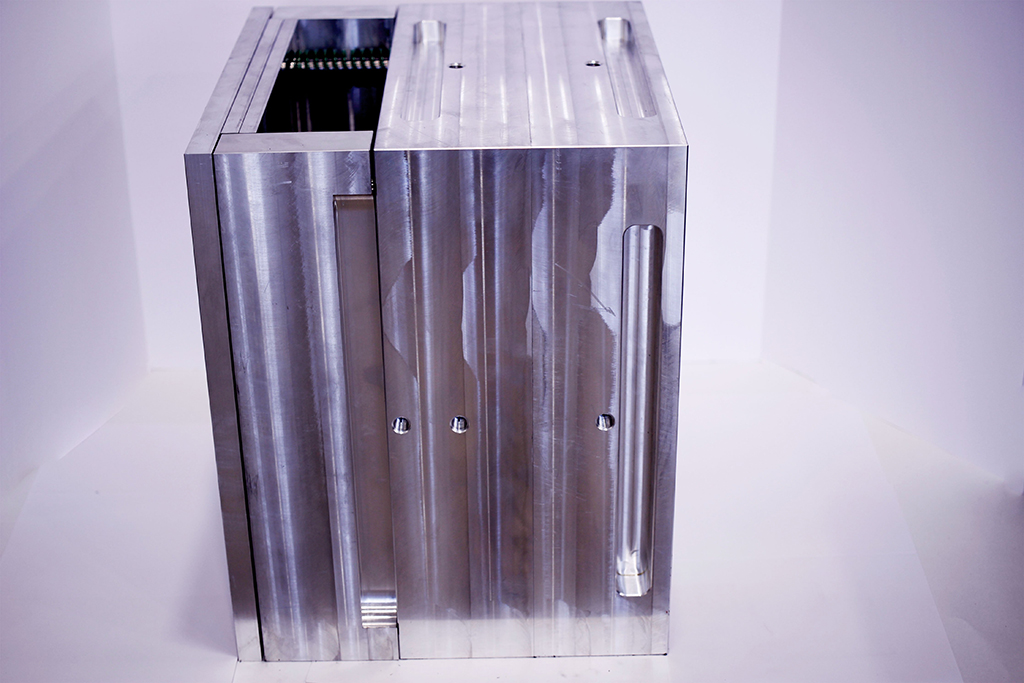

Injection Molding

Injection Molding

Despite continuing advancements in 3D-printing technology, injection molding continues to be the more efficient and cost-effective method of mass-producing plastic parts. With over 35 years experience in injection molding and mold design, Flexcim is well-equipped to shoot your plastic project into existence.

CNC Machining

CNC Machining

Flexcim Manufacturing Services Inc. offers CNC machining for both production and prototype fabrication. With experience in challenging to cut materials, we can modify pre-made parts, or machine bespoke parts or full assembles from concept design.

Prototyping

Prototyping

Flexcim’s vast experience in the industry has yielded a wealth of knowledge in many manufacturing methods, giving us a creative advantage in both traditional and rapid prototyping methods.

Store

In the fall of 2021, we launched our online store. With this outlet we hope to encourage North American buyers to look for products closer to home.

Our current selction is:

Resources

Plastic Materials

Plastic Materials

Material is a very important design consideration. It may come as a surprise to find out that there is more than one type of plastic – and for each type of plastic there are many grades and additives that affect the materials properties.

Designing Parts for Injection Molding

Designing Parts for Injection Molding

Before a mold is designed to produce an injection molded part, there are various design concepts to consider for a part to be molded properly and efficiently. This section will discuss some of these design considerations and their purposes, empowering you to design parts that require fewer iterations.

Tooling Materials

Tooling Materials

After a part has been designed or modified for injection mold manufacturing, the design of the mold tooling should be considered, specifically the material the mold will be made of. Below are a few common mold tooling materials and an overview of the benefits and drawbacks of each.